Coolant systems require proper maintenance and care. Here are some signs to look for and guides for maintaining proper coolant flow for optimal performance.

Coolant Glossary

Antifreeze: A mixture of glycol and water (typically 50:50) with a corrosion inhibitor package. An appropriate mixture balances the need for maximum heat...

Why Maintain Your Coolant

Using and maintaining a properly formulated coolant is one of the most important aspects of engine maintenance. 30% of engine breakdowns are a direct result...

Poorly Treated Indications

What happens if a diesel engine cooling system is NOT treated properly with chemicals? Corrosion of the steel and cast iron surfaces Hard water...

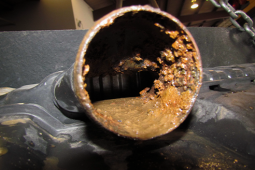

Metal Corrosion

Corrosion is the natural tendency of metals to revert back to their ore form. Cast iron, for example, will form reddish-brown iron oxide (common rust)...

Cavitation In Cooling Sytems

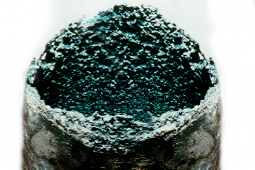

One of the most common and costly results of improper cooling system maintenance is the perforation of wet-sleeve cylinder liners. The perforation is caused...

Scale Formation

A diesel engine generates enough heat to warm a seven-room house during the winter. It must shed some of this heat to operate efficiently and prevent...

Preventing Cooling System Problems

With the Penray Fill-For-Life Program Industry experts estimate that about 40% of engine downtime is caused by cooling system problems. Understanding...

Coolant Charts

Penray recommends that all cooling system tests be performed using Penray’s Universal 3-Way Test Strips. Penray also recommends using Fleetcharge® or...

Fill For Life Program

Q. WHAT IS A FILL-FOR-LIFE PROGRAM? A. FILL-FOR-LIFE is an extended service interval (ESI) coolant program. The coolant’s life is extended to correspond...