In-ground Diesel Fuel Tanks? Time For Spring Cleaning

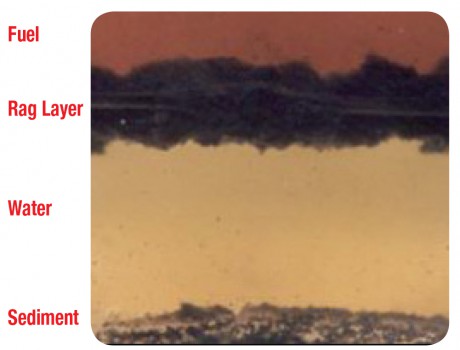

If your facility has in-ground tanks for diesel fuel storage, Penray, suggests that it’s time for cleaning. After a long, hard winter, stored diesel fuel will have accumulated moisture, corrosion, oxidation, and sludge, along with sediment deposits. If introduced into vehicles or stationary diesel engine tanks, these deposits and materials can cause a host of problems. And such issues are especially problematic with Ultra-Low Sulfur Diesel (ULSD) and bio-fuels.

If your facility has in-ground tanks for diesel fuel storage, Penray, suggests that it’s time for cleaning. After a long, hard winter, stored diesel fuel will have accumulated moisture, corrosion, oxidation, and sludge, along with sediment deposits. If introduced into vehicles or stationary diesel engine tanks, these deposits and materials can cause a host of problems. And such issues are especially problematic with Ultra-Low Sulfur Diesel (ULSD) and bio-fuels.

Fortunately help is on the way.

For those facilities that prefer to do their own treatment, Penray offers their Fuel Prep™ Biocide. It’s no secret that cold weather condensation can add significant quantities of water to stored diesel fuels. Further, new systems and processes, like vapor recovery systems and the blending of bio-fuels, can introduce water into the fuel. And once water is present, harmful bacteria and fungi can grow in these fuel supplies.

Penray’s Fuel Prep Biocide is specially blended to eliminate such microbial activity in diesel fuel supplies. By doing so, this product can help eliminate the clogged filters, clean-out costs and, in extreme cases, corrosion that can be sufficient to cause tanks to leak, resulting in expensive repairs and costly environmental remediation.

If professional help is needed, you’ll be happy to know there is a Doctor in the house…

Penray offers its exclusive Fuel Doctor program for fleets, distributors, and other facilities that store large quantities of diesel fuel. Penray’s Fuel Doctors are specially-trained diesel fuel experts who are available to make house calls. They can provide on-site diesel fuel sampling, analysis, and treatment.

Penray’s Fuel Doctors provide testing that can reveal the presence of water, evidence of corrosion, and indications of microbial growth, all of which can compromise the viability of the fuel. Samples can then be sent to off-site testing labs for confirmation of field testing results. Penray provides complimentary initial system testing free of charge. Armed with all of this data, Penray’s Fuel Doctors then schedule a consultation with the facility manager with recommendations for remediation.

If testing and evaluation suggest the need for “intensive care,” it’s comforting to know that Penray has partnered with Allied Oil & Tire Co. to provide a full range of treatment, maintenance, and remediation services for diesel fuel storage tanks. Allied has extensive history and expertise in such services and, in concert with Penray, can provide any level of corrective action needed. Allied technicians have earned confined space certification, so they are fully qualified to enter, clean and repair fuel storage tanks as needed.

Explains Penray’s Greg Mixon, Director Heavy Duty Sales , “Penray has more than a half-century of experience in developing and producing additives that support the viability of diesel fuels. Our Fuel Doctor Program is just one more example of the knowledge and customer service we bring to the diesel fuel industry.”

Adds Mixon, “The combination of our made-in-the-USA additives and treatment chemicals, along with our industry-leading Fuel Doctor program and our partnership with Allied, allow us to offer the industry’s most complete package of the products and services needed by owners and operators of diesel fuel storage facilities. They can reach out to Penray to assure that diesel fuel supplies remain fresh and potent, especially with the change of seasons upon us.”

Penray engineers recommend twice-yearly testing of in-ground diesel fuel storage supplies, with treatment as necessary to assure that fuel will not cause problems in the vehicles and equipment that rely on diesel power.

For an appointment with a Fuel Doctor, fleets and other customers can contact their Penray sales representative or call us at Ph. 800.323.6329