99.009: Converting New Trucks to the Fill-For-Life Program

Introduction:

To cost-effectively convert existing heavy-duty truck cooling systems to Fill-For-Life, Penray has identified three possible procedures that can be followed. These recommendations will help customers minimize the initial cost of the upgrade.

Recommendations:

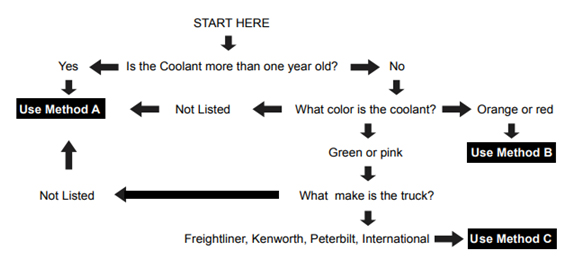

The flowchart will help easily identify the best conversion procedure:

Method “A”:

Drain and flush the cooling system with water until clear. Dispose of the old coolant properly

- Warning: Never open a hot cooling system!

- With the cooling system cool, open the stopcock and remove the thermostat. Drain the coolant, catching it for recycling or proper disposal.

- Flush the system with tap water until clear. Drain the water. Replace the thermostat and close the stopcock.

Fill the system with a properly prepared Fill-For-Life approved coolant (see bulletin 01.001)

- Mix 50% to 60% approved coolant and water -or- in temperate climates (-10 freeze point acceptable) 33% approved coolant, 1% Pencool® 3000 and 66% water -or- in warm climates (+32 freeze point acceptable) mix 5% Pencool 2000 or Pencool 3000 and water. Water needs to be relatively pure, as published in the Penray Cooling System TechFacts.

- Fill the cooling system with the coolant, check to insure correct freeze point and nitrite concentration with a Penray test strip.

Install Need-Release® filter.

- Label the filter with the date and mileage at installation.

- Install the filter hand tight. Do not use a filter wrench.

- Close and pressure-test the system.

Method “B”:

- Convert the organic system to Fill-For-Life technology

- Warning: Never open a hot cooling system!

- With the cooling system cool, open the radiator cap and add 1 pint Pencool 3000 per 4 gallons of cooling system capacity.

- If necessary, top-up the cooling system with a properly prepared Fill-For-Life approved coolant (see bulletin 01.001).

- a. Mix 50% to 60% approved coolant and water -or- in temperate climates (-10 freeze point acceptable) mix 33% approved coolant, 1% Pencool 3000 and 66% water -or- in warm climates (+32 freeze point acceptable) mix 5% Pencool 2000 or Pencool 3000 and water. Water needs to be relatively pure, as published the Penray Cooling System TechFacts

- b. Run the engine 30 minutes to mix the coolant, let the system cool, then check to insure correct freeze point and nitrite concentration with a Penray test strip.

- Install Need-Rekease Filter

- Warning: Never open a hot cooling system!

- Mix 50% to 60% approved coolant and water -or- in temperate climates (-10 freeze point acceptable) mix 33% approved coolant, 1% Pencool 3000 and 66% water -or- in warm climates (+32 freeze point acceptable) mix 5% Pencool 2000 or Pencool 3000 and water. Water needs to be relatively pure, as published the Penray Cooling System TechFacts.

- Run the engine 30 minutes to mix the coolant, let the system cool, then check to insure correct freeze point and nitrite concentration with a Penray test strip.

Method “C”:

- If necessary, top-up the cooling system with a properly prepared Fill-For-Life approved coolant (see bulletin 01.001).

- Warning: Never open a hot cooling system!

- Mix 50% to 60% approved coolant and water -or- in temperate climates (-10 freeze point acceptable) mix 33% approved coolant, 1% Pencool 3000 and 66% water -or- in warm climates (+32 freeze point acceptable) mix 5% Pencool 2000 or Pencool 3000 and water. Water needs to be relatively pure, as published the Penray Cooling System TechFacts.

- Run the engine 30 minutes to mix the coolant, let the system cool, then check to insure correct freeze point and nitrite concentration with a Penray test strip.

- Install Need-Release filter.

- Label the filter with the date and mileage at installation.

- Install the filter hand tight. Do not use a filter wrench.

- Close and pressure-test the system.

Refer to technical bulletin 01.007 for long-term maintenance recommendations of Fill-For-Life systems.