01.016 Pencool SCA Recommendation: Deutz Marine Engines

Introduction:

This bulletin will provide specific information on the use of Pencool Supplemental Coolant Additive (SCA) in Deutz AG engines for marine applications. This bulletins covers the 1045M and 1013M marine service engines.

Service Recommendation:

- Initial Fill Coolant:

- Antifreeze Systems: Use 50% Ethylene Glycol based low silicate, fully formulated coolant that meets TMC purchase specification RP-329 (ethylene glycol base) or RP-330 (propylene glycol base).

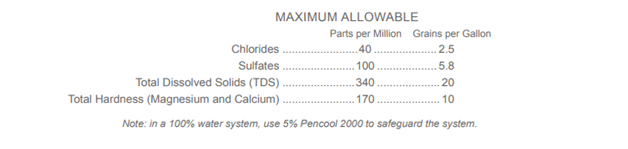

Note: if RP-329 or RP-330 coolant is unavailable, mix a coolant using 50% ASTM D-4985 specification antifreeze, 3% Pencool 3000 with Stabil-Aid®, and 47% purified water to safeguard the cooling system against corrosion and liner pitting. - Water Only Systems: Use of distilled or de-ionized water that eliminates the adverse effects of minerals in tap water is preferred. High levels of dissolved chlorides, sulfates, magnesium, and calcium in some tap water causes scale deposits, sludge deposits and/or corrosion. These deposits have been shown to result in water pump failures and poor heat transfer, resulting in over-heating. If tap water is used, the mineral content in the water must be adhere to the following chart:

- Antifreeze Systems: Use 50% Ethylene Glycol based low silicate, fully formulated coolant that meets TMC purchase specification RP-329 (ethylene glycol base) or RP-330 (propylene glycol base).

- Maintenance:

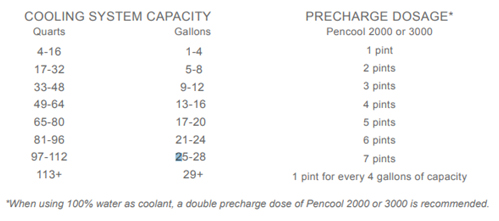

- Precharge System: To start a Pencool 2000 or 3000 program, refer to the chart for precharge dosages that will bring the system to full protection:

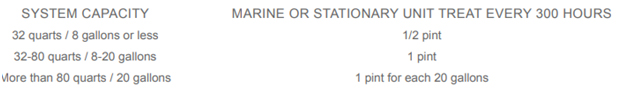

- Maintain System: When used properly as a preventive maintenance program, Pencool 2000 and 3000 help reduce costly downtime, maintenance, and engine wear.

- Precharge System: To start a Pencool 2000 or 3000 program, refer to the chart for precharge dosages that will bring the system to full protection:

- Cooling System Testing Procedures:

- Test Kit Procedures:Tuse a Penray 2-Way Heavy Duty Test Strip (part number TS-100 or TS-102) to measure nitrite and glycol concentrations. Cavitation/corrosion protection is indicted on the strip by the level of nitrite concentration. Freeze/boil-over protection is determined by glycol concentration. Use the test strip as follows:

- For best results, test while the coolant is 50∞ – 140∞F (10∞ – 60∞C). Dip the strip into the coolant for one second. Remove and shake to eliminate excess fluid. Immediately compare end pad (% Glycol) to the color chart on the bottle.

- Sixty seconds (one minute) after dipping compare other pad (Nitrite) to the color chart on the bottle

- Coolant Analysis: A laboratory coolant analysis program is available through authorized Penray dealers (part number PTK-103). To verify long-term coolant acceptability, submit a sample for coolant analysis every three (3) years, 100,000 miles, or 4,000 operating hours, whichever comes first.

- Test Kit Procedures:Tuse a Penray 2-Way Heavy Duty Test Strip (part number TS-100 or TS-102) to measure nitrite and glycol concentrations. Cavitation/corrosion protection is indicted on the strip by the level of nitrite concentration. Freeze/boil-over protection is determined by glycol concentration. Use the test strip as follows: